- HOME

- APPLICATION

- WIRE & CABLE

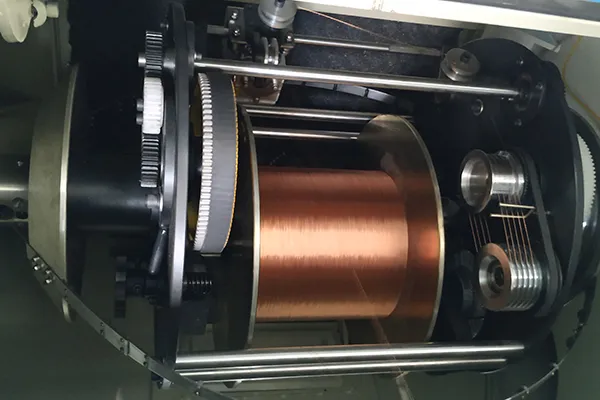

- WIRE DRAWING & ANNEALING

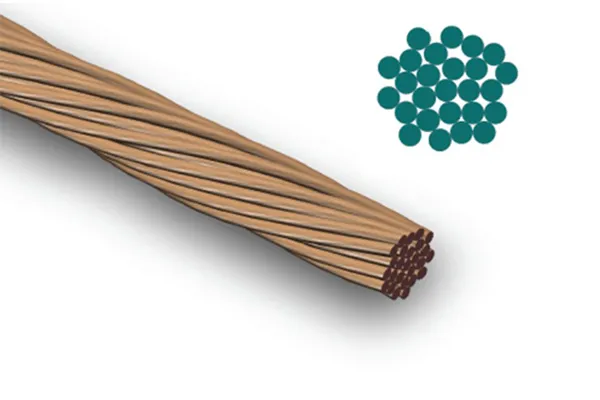

- WIRE BUNCHING & STRANDING

- WIRE INSULATION & SHEATHING

- WIRE LAY UP & TWISTING

- TAPPING & SCREENNING

- COILING & PACKAGING

WIRE DRAWING & ANNEALING

WIRE BUNCHING & STRANDING

WIRE INSULATION & SHEATHING

WIRE LAY UP & TWISTING

TAPPING & SCREENNING

COILING & PACKAGING

- METAL TUBES

- PACKAGES

- ABOUT

- CONTACT